Use case Lube

USE CASE LUBE: COLLABORATIVE ROBOTIC SYSTEM FOR THE ASSEMBLY OF KITCHEN FURNITURE

At LUBE, two applications involving the collaboration between operator and robot have been examined and developed.

The first application consists in the study and development of a robotic system that operates in the assembly line and supports the operator in the final activities of assembly, registration, cleaning and quality control before the packaging of the furniture. A human-robot collaboration system has been conceived and designed in which the robot positions the furniture in an optimized position according to the anthropometric characteristics of the operator, the product dimensions and the specific characteristics of the task. The goal is to ensure greater safety and reduce ergonomic risks for the operator. The developed system integrates different devices and different technologies. In particular, it allows to recognize the human presence, the product and the

requirements of the task and adapts, accordingly, the position of the product and the configuration of the robot. In this regard, an optimization model has been developed to identify the product position automatically, respecting technological and ergonomic constraints and minimizing the distance between the operator's chosen product position and the theoretically ideal one among all the admissible positions. Moreover, a camera system has been implemented to reconstruct the human skeleton and calculate the main anatomical angles in order to evaluate the ergonomic risk in a non-invasive way and in real-time. Finally, the system and the model were tested in the laboratory with excellent results.

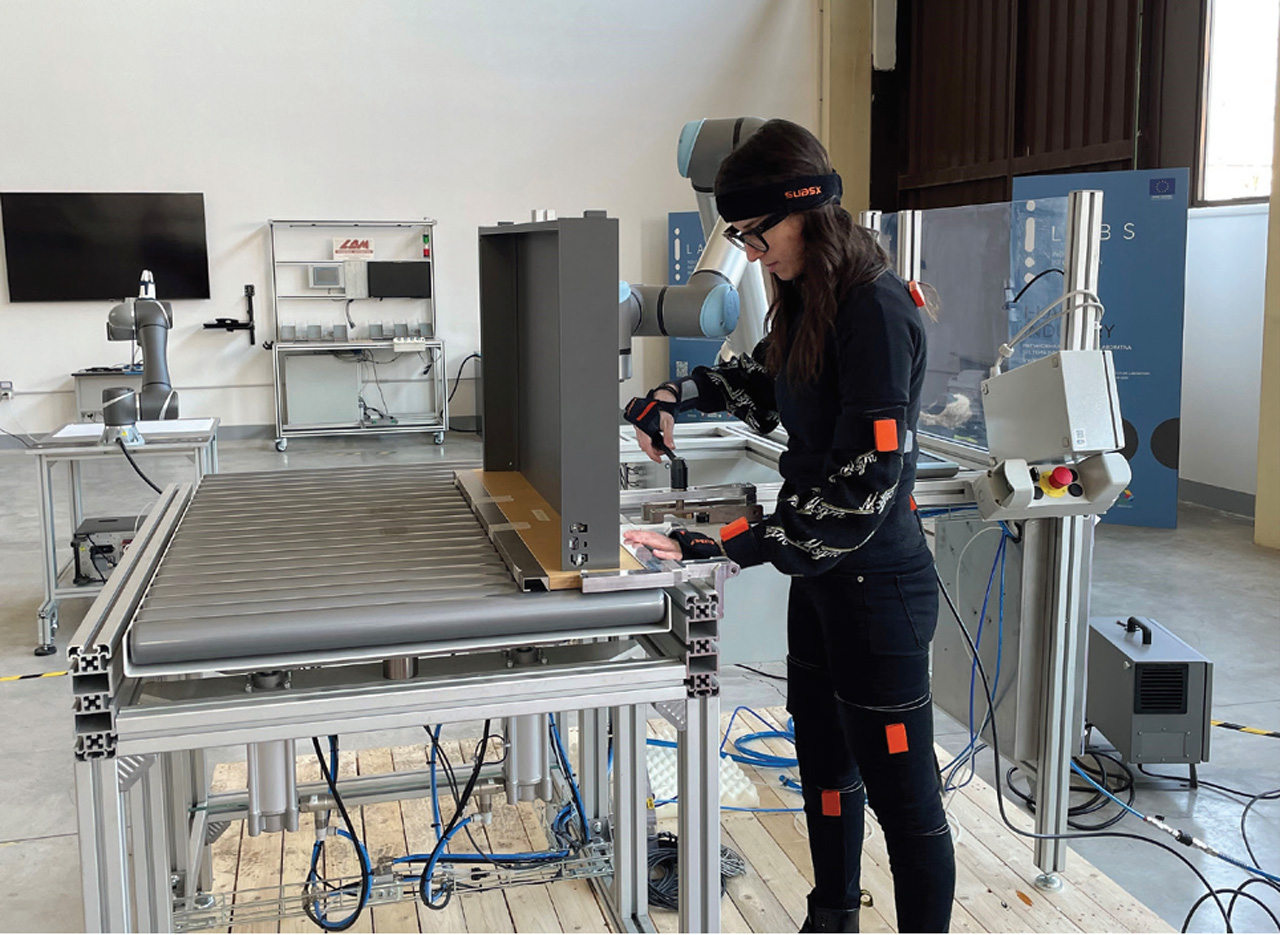

The second application considered the study, development and implementation of a collaborative robotic system for screw insertion on kitchen drawers. The analysis of the productivity and ergonomics of three manual workstations of the pot-and-pan drawer assembly line revealed ergonomic risks due to repetitive movements and incorrect posture. It was therefore decided to introduce a collaborative robot, totally modify the layout of the station and rebalance the line to facilitate the screwing operation while still ensuring the necessary level of productivity. A collaborative cell has been designed and realized, carrying out a risk analysis and several simulations of the process, until reaching the desired results in terms of ergonomics and productivity.