Case Study

Urrà

Robot Usability and Process Reconfigurability

BACKGROUND

In recent years, the development of new robots with refined manipulation, vision and understanding capabilities of their surroundings is driving a new industrial revolution. With the advent of Industry 4.0, production lines are characterized by a constant renewal that points towards automation and artificial intelligence.

The URRÀ project analyzed the latest technologies related to the technological field of collaborative robotics and Cyber Physical Systems (CPS) and techniques for human-robot collaboration and reconfigurability of production processes, which have CPS systems directly integrated into Manufacturing Execution Systems (MES), were implemented and validated.

The objective achieved by the project was to simplify the use of robots in industry, allowing robots to become "smart", i.e. able to learn autonomously the task to be performed and to "take decisions" based on the current production situation in which they are, and to simplify their interconnection at the level of industrial processes.

The technologies developed in a first phase of research and development, were then implemented in three different use cases at companies in the area.

DEVELOPMENT, INTEGRATION AND VALIDATION IN REAL APPLICATIONS

As a final result, the project has created industrial prototypes with a high degree of flexibility. These prototypes have demonstrated the feasibility and effectiveness of the technological solutions adopted compared to classic centralized automation solutions and/or manual work by an operator.

Use case Zannini

ADVANCED ROBOTIC SYSTEM WORKING IN COLLABORATIVE MODE FOR THE MANIPULATION OF TURNED COMPONENTS

The study has led to the development of a robotic test cell for the measurement of small cylindrical pieces of metal nature performed with a Fanuc collaborative robot, replacing the operator in the manual and repetitive work of picking. The automation of the process, not only increases the quality of the work, but ensures a strong increase in productivity since a single operator is able to manage several robotic stations simultaneously.

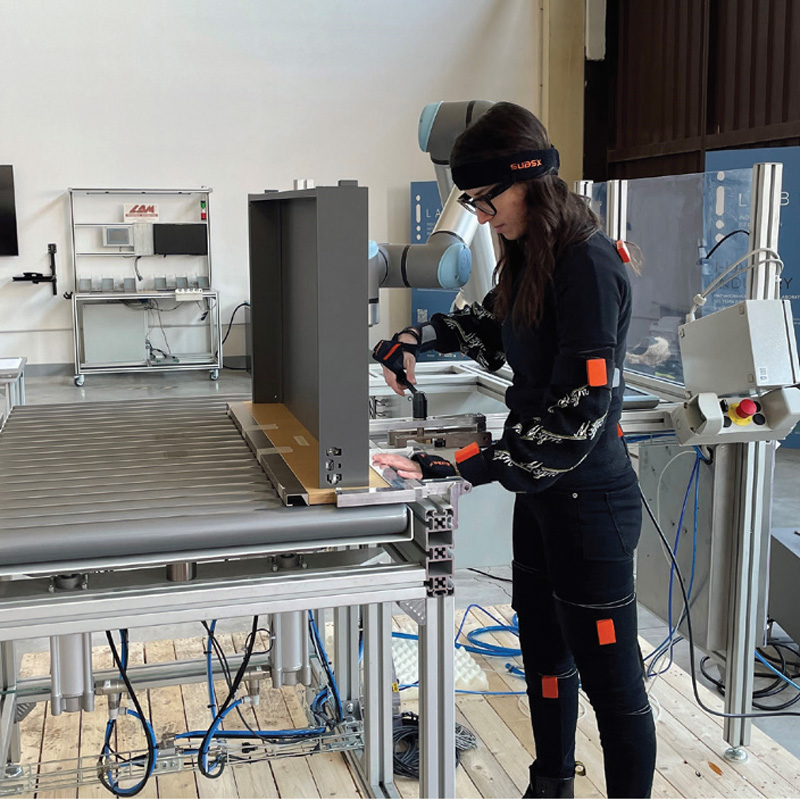

Use case Lube

COLLABORATIVE ROBOTIC SYSTEM FOR THE ASSEMBLY OF KITCHEN FURNITURE

In LUBE two applications involving the collaboration between operator and robot have been examined and developed. The first application consists in the study and development of a robotic system that operates in the assembly line and supports the operator in the final activities of assembly, registration, cleaning and quality control before the packaging of the furniture. The second application considered the study, development and implementation of a collaborative robotic system for the insertion of screws on kitchen drawers.

Use case Loccioni

ADVANCED MANIPULATION OF OBJECTS IN THE PRODUCTION LINE

The manipulation of different objects done automatically by a robot without a priori information is one of the challenges of these last years. Nowadays, a robot to manipulate objects must have a lot of a priori information, such as its dimensions, its position, the material it is made of, etc. The objective of the project and the prototype developed was to verify the feasibility of the use of convolutional neural networks called Quality Grasp - Convolutional Neural Networks (GQ-CNN) that through the 3D image of the object provides the robot with the coordinates of the best grip for the robot.